- NeveRest Orbital 14:1

- for a faster drive train, the 14:1 output of these motors is preferred

- NeveRest Orbital 20:1

- These motors can handle moving around more weight at a more consistent speed

- NeveRest Hex 14:1

- for a faster drive train, the 14:1 output of these motors is preferred

- Hex output shaft for easy integration

-

NOTE: due to sizing, the encoder is not accessible on the hex version of this chassis

- NeveRest Hex 20:1

- These motors can handle moving around more weight at a more consistent speed

- Hex output shaft for easy integration

-

NOTE: due to sizing, the encoder is not accessible on the hex version of this chassis

Understanding Part Numbers

FIRST Tech Challenge Chassis Configurator

Structure & Usage

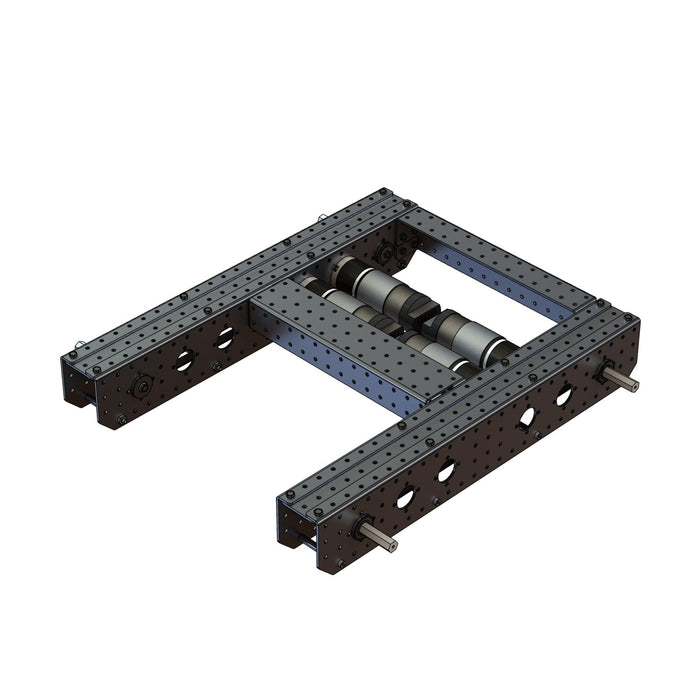

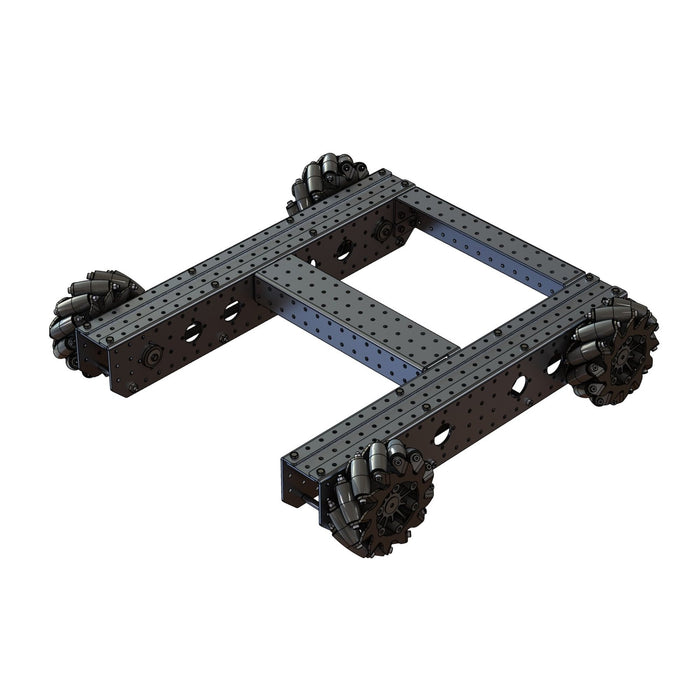

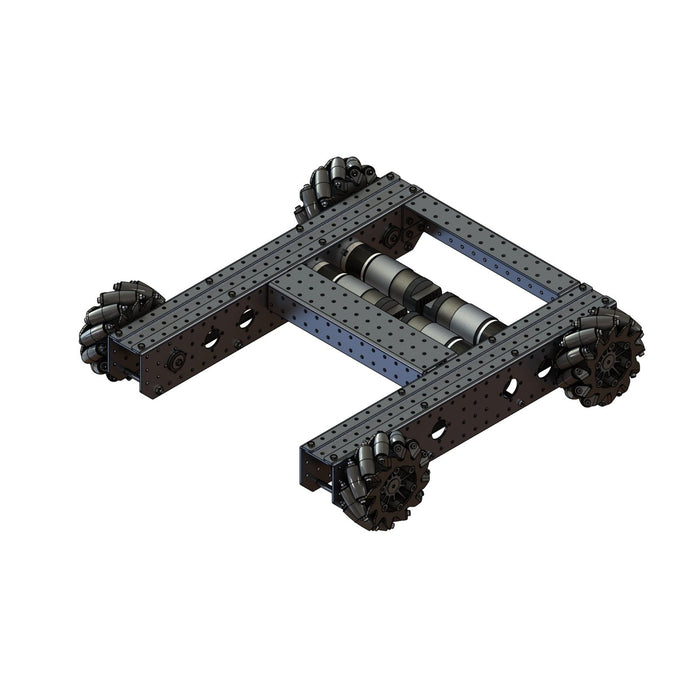

The foundation of this drive base is a set of aluminum plates, brackets, and struts that provide a sturdy frame to build upon. All of the holes in the sheet metal are on a global 16 mm pattern, which integrates with numerous structure components across several vendors.

The cross plate can also be moved into a number of alternate locations to best suit your robot's configuration needs. Without motors and wheels, the chassis is about 4 pounds.

Performance, Rugged, Configurable

The MecanAM Chassis was designed with the FIRST Tech Challenge community in mind. The usage doesn't stop there, however, it can work well for many other robotic competition platforms of similar size. Years of lessons from designing, building, and competing with championship-winning drive systems have gone into this robust drive system that integrates well with teams' existing FTC parts.