- Description

- Specifications

- Documentation

-

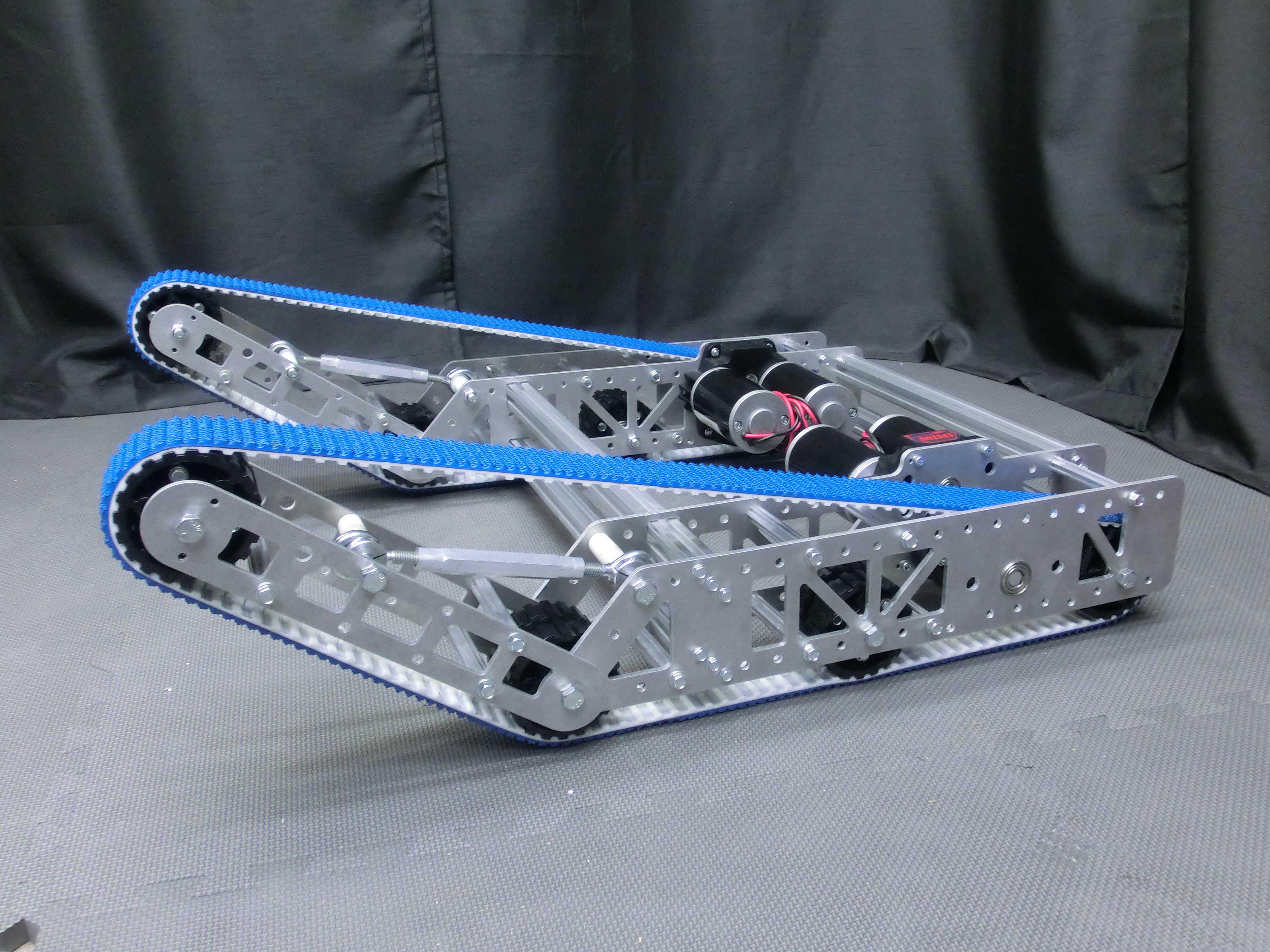

Four robust molded pulleys direct the path of a belt, driven by an optional AndyMark gearbox or transmission. Two of these modules can be used to create a tank drive-base. The Rhino Track Drive features rigid, 3/16 inch thick aluminum plates and an easily adjustable belt tension mechanism. This is an ambidextrous module, so it can be used for the left or right side just by switching the plates from one side to the other. The Rhino Track Drive Module ships in an un-assembled kit. Please see the assembly instructions for assembly assistance.

This module includes one belt. In order to create a typical drive system for most applications, two modules will need to be purchased. We suggest the use of four (4) pieces of 1 in. wide extrusion as bracing structure between two Rhino Track Drive Modules. Pictures of this setup version are shown below.

During normal use of the Blue Nitrile Tread, the blue rubber may begin to delaminate (split apart from the timing belt). If this happens, please follow these steps to fix the belt:

- Keep the belt mounted to the drive pulley mechanism (do not remove the belt from your robot)

- Clean both surfaces where the delamination is happening, removing debris and dirt

- Take time to allow the cleaned area to dry

- Use a rubber to rubber adhesive such as super glue. This has great bonding properties to adhere the tread to the urethane timing belt material.

- Keep pressure on the newly glued area by moving this area over an end pulley. This applies continual contact between the rubber and timing belt.

- Wait 20-30 minutes for the adhesive to cure.

Not Included:

- A gearbox, such as the Toughbox Mini, as shown in the layout print and example pictures.

- Bumper brackets are also not included.

Belt Tension:

- Proper belt tension is detailed in this document.

Included Items:

- 1 - 250 Sprocket and Pulley Spacer (am-0207a)

- 8 - 3/8 in. Round Shielded Bearing (1614ZZ) (am-0209)

- 4 - 985x375 Spacer (am-0441)

- 6 - 10-32 Nylock Nut (am-1042)

- 6 - 10-32 x 1.25 in. Button Head Cap Screw (am-1260)

- 6 - 3/8-16 x 4.25 in. Hex Head Bolt Grade 5 (am-1297)

- 6 - 3/8 in. x 1/16 in. Washer (am-1393)

- 6 - 3/8-16 Nylock Jam Nut (am-1394)

- 2 - Aluminum Spacer 0.75 x 0.382 x 0.625 in. (am-1451)

- 1 - 0.5 in. Hex HD Collar Clamp (am-1526)

- 20 - 1/4-20 x 0.75 in. Slotted Indented Hex Thread Cutting Screw (am-1591)

- 4 - Pulley, Timing 42 tooth, HTD profile, 15mm wide, polycarbonate (am-2234)

- 2 - Collar Clamp, 3/8 in. Bore, Aluminum (am-2382)

- 1 - 500EX Hex Hub (am-2568)

- 10 - Churro Aluminum Tube 3.375 in. +/- 0.125 in. Long (am-2569)

- 1 - 85 Tooth 5 mm 15 mm Wide Timing Gates Belt (am-2703)

- 1 - 1/2 in. Hex Shielded Flanged Bearing (FR8ZZ-HexHD) (am-2986)

- 8 - 20T Track Drive Pulley (am-3298a)

- 1 - Rhino Track Drive Outside Plate (am-3318)

- 1 - Rhino Track Drive Inside Plate (am-3319)

- 2 - Tank Tread Upper Bar Plate (am-3320)

- 1 - Tank Tread Turnbuckle (am-3321)

- 1 - 85 Tooth 5 mm 15 mm Wide Timing Belt (am-3661)

- 2 - 0.375 in. Hex Molded Spacer 0.063 in. Long (am-3947-063)

- 2 - 0.375 in. Hex Molded Spacer 0.188 in. Long (am-3947-188)

Included with am-3322

- 1 - Blue Roughtop Nitrile Track Timing Belt (am-3288)

Included with am-5514

- 1 - Black Flat Urethane Track Timing Belt Tread (am-4017)

-------------------------------------------------------------------------------------

Example photos of a drive system made with two Rhino Track Drive Modules:

-

- Material: Carbox Nitrile Rubber or Black Urethane

- Overall Length: 30.44 in. with Upper Arm at 34° angle, (31.3 in. with Upper Arm at 5° and moved in to secondary pivot point)

- Weight: 8.9 lbs. (no gearbox, no motors)

- Width: 3.75 in.

-

CAD Files

am-3322 Rhino Track Drive Module.STEP

am-3322 Rhino Track Drive Module Left.STEP

am-3322 Rhino Track Drive Module Right.STEPLayout Prints

am-3322 Rhino Track Drive Module.PDFGuides

am-3322 RhinoTrackDriveModuleV3.pdf