The information provided on this page is retained for posterity.

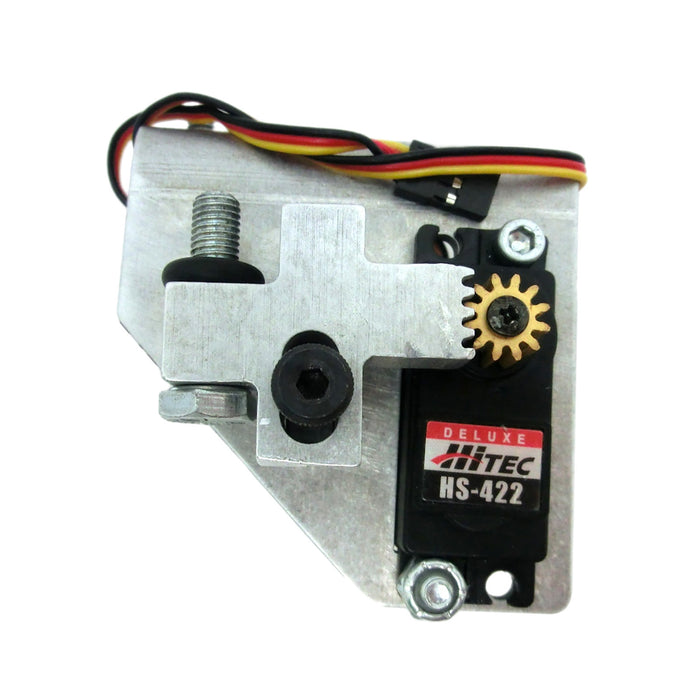

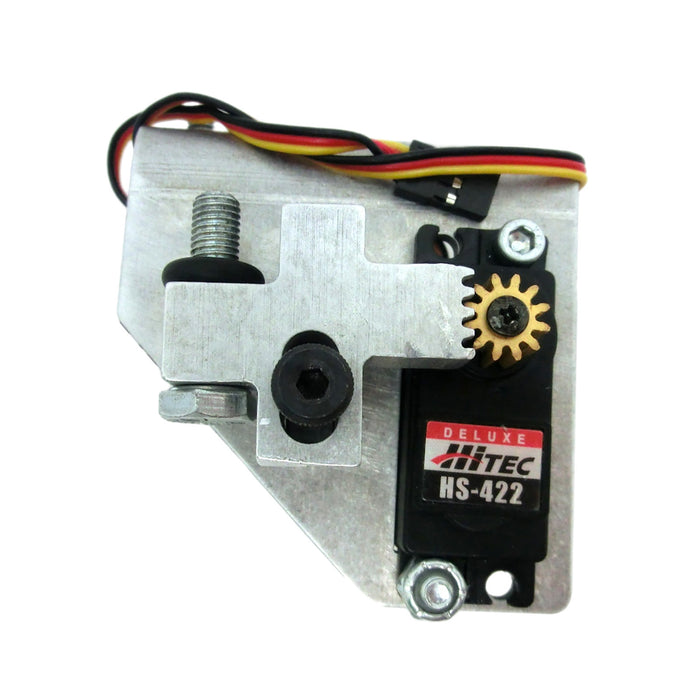

'Good Idea, poor execution... Bolt and Shifter did not line up after mounted to transmission. Linear slide did not fit on key. Need to machine the key to lower the slide and open the slide to fit the key. After we did this to make the bolt and shifter line-up we noticed then the linear slide hit the servo. We then machined the bottom of the slide across the teeth to clear the servo. We believe the sheet metal bracket was not correct. It needed to be lower, around 1/8', and we believe this would of solved the alignment issues.'

They are a neat idea but did not provide the amount of force we ended up requiring.

'The 8-32 Nylock Nuts are too large to mount the servo to the bracket. The interference between the nut and servo housing prevents the 8-32 screws from going in straight.

The 10-32 screws that mount the Servo Bearing Block prevent the 10-32 Shoulder Bolt from fully seating since it threads into the opposite side of the Servo Bearing Block.'