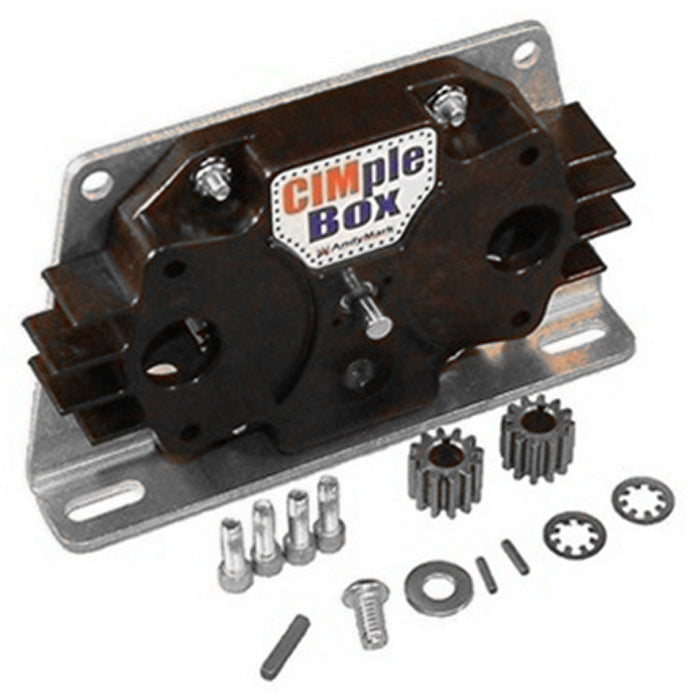

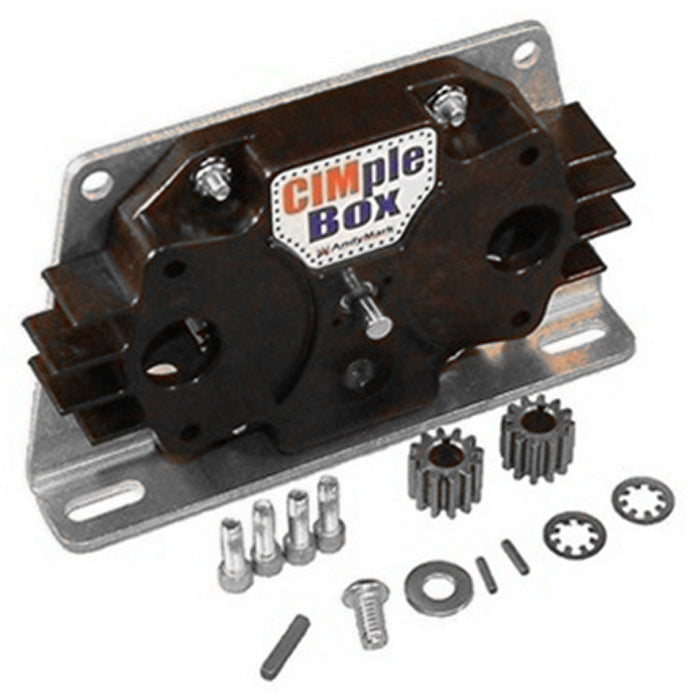

We needed a low format gearbox to add a spooling pulley for a two stage vertical slide extension. We had to modify the box and shaft to achieve the result we wanted, using a 1/2 inch hex drive shaft with the magnet cut off and a second snapping cut into the shaft. We then had to use a step drill to bore out the side holes to allow the gears from the cim motors to extend through the bracket. The single down bolting cut bracket would allow flex in our application and the back of the two cim motors had to be strapped down to prevent flex.

Maybe we picked the wrong gearbox for our application but with the shortages during build season we got what we could and made it work.